|

|

|

Features

Update 2019/11/25

Persistent Organic Contaminants

brought to you in part by

THE DESTRUCTION OF PFAS IN WATER WITH A PLASMA REACTOR

By Suzanne Forcese

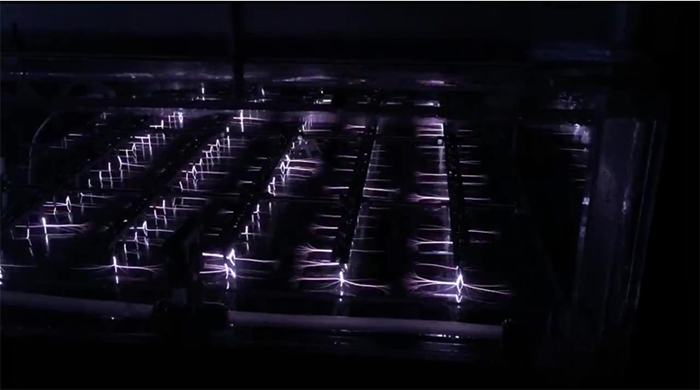

Plasma Reactor In Action Destroying PFAS Photo Courtesy Dr. Stephen Richardson (GSI Environmental)

Under the Great Lakes Water Quality Agreement, Canada and the United States agreed to develop a list of Chemicals of Mutual Concern and create plans to deal with them. Specific poly-and perfluoroalkyl substances (PFAS), known as perfluorooctanoic acid (PFOA) and perfluoroctane sulfonate (PFOS) were among the first items both nations added to that list in 2016. Part of dealing with PFAS contaminants involves cleaning up what is already in groundwater supplies – a difficult task up to this point due to the recalcitrant nature of PFAS.

Clarkson University in Pottsdam, New York and GSI Environmental in Austin, Texas have demonstrated a cost-effective and sustainable environmental solution for treating groundwater containing PFAS.

WaterToday spoke with both Dr. Selma Mededovic Thagard, Professor of Chemical and Biomolecular Engineering; and Dr.Stephen Richardson, P.E., P.Eng of GSI Environmental Inc.

Drs. Mededovic and Richardson recently completed the first field demonstration of an innovative plasma-based technology for the treatment of PFAS-impacted groundwater. The two week project was successfully conducted at Wright-Patterson Air Force Base in Ohio, USA.

Plasma-based water treatment uses electricity to convert water into a mixture of highly reactive species (i.e. plasma) that rapidly and non-selectively degrade recalcitrant organic contaminants, including PFAS and many others.

Mededovic,( who has degrees in chemical engineering from the University of Zagreb, Croatia, and Florida State University, as well as appointments at the Toyohashi University in Japan and Colorado State University), was initially caught by surprise at the entire scope of this endeavor. “I discovered this by accident,” she told WT. “I was doing tests with pharmaceuticals and we decided to test several other contaminants. To my disbelief, tests on PFAS kept coming up with the same results. Finally I had to accept the fact that I was on to something. My expertise is in reactive design. I didn’t know anything about PFAS until my collaborators told me it was a big problem.”

They have been dubbed “the forever chemicals”. PFAS are a family of synthetic chemicals that are persistent in the environment and our bodies. First developed in the 1930’s and mass marketed in the 1940’s and 50’s, these ubiquitous chemicals have been used in the production of non-stick cookware, water and stain repellent textiles, carpeting, hoses, cable and gaskets, personal care products, paint, cleaning products, food packaging, and photographic film additives.

PFAS have been extensively used in fire-fighting foams for emergency and training purposes on military bases and in the aerospace industry. Therein lies the problem. Those PFAS “migrate very slowly through the soil making their way into groundwater and drinking water supplies and may not be detected for years”. (Health Canada)

The chemical bonds that give PFAS their heat, oil, and water resistant qualities are so resilient that they do not break down in the environment or the human body. Studies have suggested a potential connection of PFAS to pregnancy complications, developmental disorders, immune and thyroid disorders, changes in cholesterol, obesity, liver effects, kidney disease and cancer.

Although PFAS are no longer produced in Canada or the US, they may be present in imported products.

The signature elemental bonds of fluorine and carbon are what make these substances so difficult to degrade (or break apart) and their legacy persists in groundwater. According to the US Department of Defense there are at least 300 military installations and 44 civilian airports known to be contaminated by fluorinated compounds (PFAS). Because of their slow migration through the watershed, PFSA levels are expected to show an increase over time. “To date the scope of this issue has not been evaluated in Canada.” (Environmental Sciences Group, Royal Military College of Canada)

PFAS water contamination is revealing itself as an emerging concern.

Understanding how important stewardship is to the natural world, the environmental consulting firm, GSI Environmental, became involved in the plasma-based water treatment project when Principal Engineer Stephen Richardson was introduced to the technology by a client. “I spent some time looking into the technology and reached out to Selma.” It was indeed a perfect fit.

“We had developed the technology,” Mededovic said of her co-investigator, Thomas Holsen, PhD, and their students, but we needed someone to upscale our model for the field”

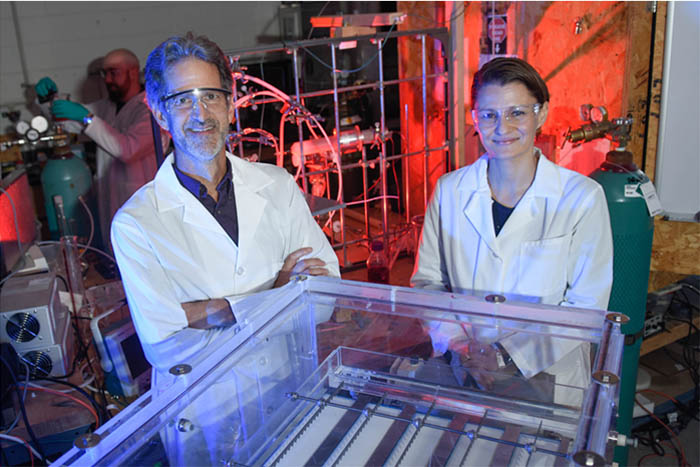

Dr. Thomas Holsen & Dr. Selma Mededovic Thagard with plasma reactor in the Lab at Clarkson University. Photo Courtesy Clarkson University, Pottsdam, New York

“We submitted a proposal,” Canadian born (former Waterloo University grad), Richardson told WT. “It took us a couple of years to move from bench-scale reactor to a fully-operational mobile treatment system that we could transport to various sites.” Richardson and his colleague, Poonam Kulkarni, P.E., designed the tech ready trailer. From the design through to construction and safety checks, the mobile unit was good to go in about 18 months.

Clarkson & GSI Environmental Remediation Mobile Lab (L to R: Taylor Borgfeldt (GSI) Poonam Kulkarni (GSI), Stephen Richardson (GSI), Chase Nau-Hix (Clarkson), Nick Multari (Clarkson), Tom Holsen (Clarkson) and Selma Mededovic (Clarkson)

Photo Courtesy Dr. Stephen Richardson (GSI Environmental) and Dr. Selma Mededovic (Clarkson University)

Under an Air Force Civil Engineer Centre contract with Clarkson University the mobile unit was used in the first field test at Wright-Patterson Air Force Base.

“We had two goals for the field demonstration. First we wanted to find out how the trailer would operate under field conditions and second we wanted to determine if we could achieve our treatment goals of less than 0.07 parts per billion,” said Richardson. The test was a success on both counts. In fact expectations were exceeded. “We were expecting to run upwards of ten times per cycling event to achieve optimal results but were able to do it in two,” said Mededovic.

Plasma based water treatment uses electrical discharges formed in contact with or in the vicinity of water and argon gas to degrade chemicals in contaminated water. A plasma reactor does not remove contaminants but completely destroys them without generating waste or without the need for added chemicals. “The argon gas concentrates PFAS at the gas-liquid interface and plasma is generated at that interface which destroys the PFAS,” Mededovic explained.

“Following optimization of the reactor operating conditions, we treated over 300 gallons of water during the second phase of the demonstration,” Richardson said.

“This is the only technology that actually destroys PFAS molecules that has been demonstrated at this scale, it doesn’t just remove them from the water,” said Dr. Tom Holsen. “All of the other demonstrations that we’re aware of remove it from the water through filtration so there is still a PFAS containing waste. Our method actually destroys PFAS.”

The objective of the Air Force funded project was to transition the technology from the lab to the field and optimize operating conditions of the mobile system. “Now that we have had success treating groundwater we need to put our system to the test on other sources of water with different PFAS compositions.”

Both Dr. Selma Mededovic and Dr. Stephen Richardson agree they would welcome the opportunity for more field tests. “A trip to Canada is definitely possible. I’m open to exploring new opportunities to test the plasma technology,” Richardson concluded.

suzanne.f@watertoday.ca

|

|

|

Have a question? Give us a call 613-501-0175

All rights reserved 2026 - WATERTODAY - This material may not be reproduced in whole or in part and may not be distributed,

publicly performed, proxy cached or otherwise used, except with express permission.

|

| |