2021/11/22

brought to you in part by

MONCTON DRINKING WATER

Moncton Water Plant Adapting technology for changing water conditions

WT Interview with Nicole Taylor, Director of Water and Wastewater, City of Moncton, New Brunswick, November 17, 2021

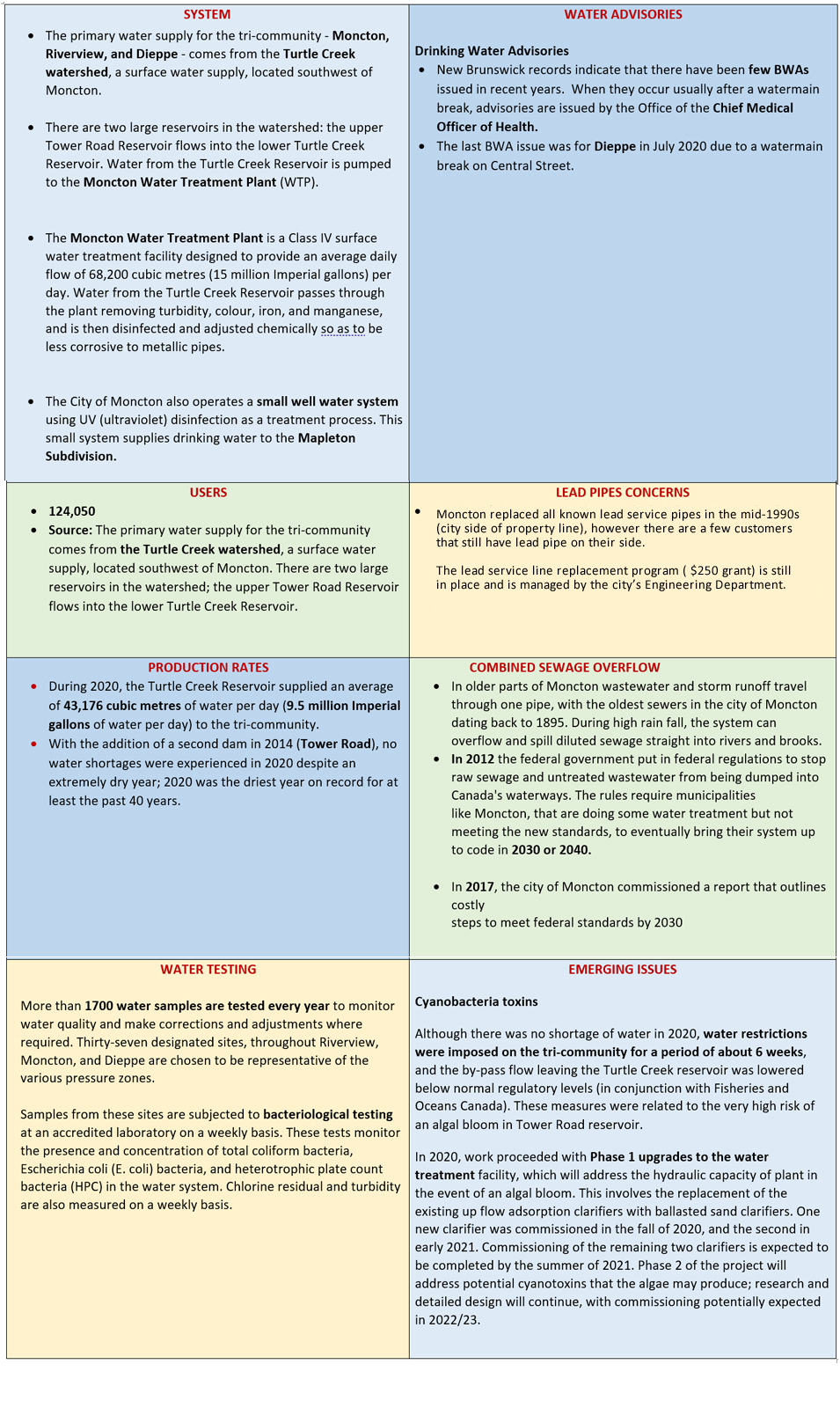

WT: This is a continuing series of interviews around city water in Canada. I have with me Nicole Taylor, she is the Director of Water and Wastewater for the City of Moncton, New Brunswick. Thanks for doing this, Nicole. Could you give the viewer a sense of what your drinking water system is, a little bit about its operation, and how many people it supplies water to?

Taylor: Moncton is a community in southeastern New Brunswick. It’s a Level 4 water treatment plant, designed for 100 megalitres per day, it provides water for about 125000 people including the municipalities of Moncton, Dieppe, and Riverview.

WT: One of the reasons I like doing the City Water Series is that each city is unique, I read that your river is affected by the tides, can you tell us about that?

Taylor: The Petitcodiac River passes through the tri-community, and it is impacted by tides, however, our drinking water system source is from two reservoirs in the Turtle Creek watershed 10 km south of the city.

WT: There was a fair amount of money from the federal government, this applies to Moncton drinking water, “the project will replace the plant’s current water clarification system with a new dissolved air flotation system to prevent algal blooms from reducing the flow capacity”. Can you explain, why do you need such a thing?

Taylor: In the end it went through a formal RFP process, so even though the request was for a dissolved air flotation system, that’s not the final technology that was chosen.

Phase I of our water treatment plant mitigation strategy was to replace the existing upflow adsorption clarifiers with a different type of technology that would be more suitable for incoming algae.

So, what was chosen through the RFP process was a “ballasted sand” system. At this point, we have four clarifiers, and all four have now been replaced with the new ballasted sand system.

WT: And that system takes all the cyanobacteria out of the water?

Taylor: Nothing is 100%, the point of the new technology was to improve the hydraulic capacity of our plant in the event of an algal bloom at our intake, we are trying to prevent our water treatment plant from plugging up.

WT: If there is a bloom, and I’m on your drinking water system, what you have installed here will catch most of it or 99% of it?

Taylor: It's a high percentage. That is basically Phase I, to address hydraulic capacity, to prevent the plant from plugging up. That will remove a good proportion of the algal cells. There is still some that will get through that clarification process, just like there are some solids and other parameters that will get through any clarifier process. And then that will get trapped in the filters after that. So essentially without the new modified system, the clarifiers would have plugged up, and the filters would have plugged up, the system would have been overwhelmed with the solids.

WT: You are counting on all this screening system to take out most, if not all of the cyanobacteria?

Taylor: Right, we want to remove them with a different type of clarifier process that won’t plug up. The clarifier process that we originally had behaves very similar to a pre-filter, which with algae - if you can picture algae as microscopic jellyfish. If you put those on a filter, you can pretty well picture that it’s going to clog very quickly.

So, the new process doesn’t have that same type of technology, it has a different technology that will not cause plugging. That’s Phase I.

Cyanobacteria, if you picture it like an egg, cyanobacteria is the egg with no hard shell, just the thin film around it, it’s easy to break that little film. If the water goes over sharp rocks, it can rip that membrane, and it releases the inside guts of the algae. So, what we want to do in our new process with the new clarifiers is, we want to keep the algal cells intact. We want to remove as many algae intact in the clarifiers, then they go to our waste stream.

We want to do that because there are some algae that can generate cyanotoxins. Not all are able to generate toxins, and the ones that are able to, don’t always generate toxins. So. It’s a bit of a tricky game. If you keep the cells intact, you keep the toxins inside, kind of like the yolk of the egg, you want to keep that inside. We want to remove the cells intact, without breaking that membrane. Our new technology can keep the cyanobacteria cells intact so when we remove them through the clarifier, we take all the toxins that may or may not be inside them.

WT : So, you have another process that you want to add to your filtration plant coming up, or has this system done enough?

Taylor: Phase I was the upgrade of the clarifiers, the ballasted sand process, collecting the algae intact and preventing the plant from clogging. Phase I is essentially complete right now.

Nothing is 100%, so in the water supply, there are cells that have already ruptured. They could have passed against a rough rock, or a sharp edge of some kind, or they could just die, which breaks the membrane as well. If there is an algal bloom, and it is producing toxins, you would have some of those in your raw water, in the untreated water coming into your plant. So those that have already ruptured will pass right through the clarifier process.

Now, Phase II is to remove the cyanotoxins that get through, from the algae cells that have already ruptured and released toxins into the water. That process is just beginning. There are several technologies available, right now we are in the research phase to determine what is the best option for Moncton. Every water treatment plant is unique, what works in one place doesn’t necessarily work in another, it depends on the concentration of algae, the type of algae. There is a lot of research that goes into determining that. Eventually, we will choose the appropriate technology for Moncton, then we will go through the detailed design, engineering construction, and commissioning phase so that the whole phase is a 3-year project.

WT: Is it 3 years from now to have the system that will catch the cyanotoxin?

Taylor: A little bit less, we are into it right now, its probably closer to 2 and a half years left. (Interview continues below Overview)

OVERVIEW

WT: Are there any clear front runners?

Taylor: Not yet we aren’t at that point yet. We have a research plan, that is multiple phases, multiple experiments to determine what will work best on our particular raw water supply. It also must fit in with our existing water treatment plant process, what will suitably fit with our existing process. Every plant is a bit different depending on what they must treat for in their raw water. Some are fairly simple, some are a little bit more complex, but still conventional; some are very advanced, there are a lot of factors to consider.

WT: There is also something unique about the drinking water system in Moncton, if I understand right, the system was privatized at one time, with private operator Veolia, and then if I understand right, Public Service Alliance of Canada announced that the system was taken back by the City of Moncton, is that accurate?

Taylor: The water treatment plant is still operated by a third party, and that is Veolia, the City of Moncton does not operate the water treatment plant. The Water Treatment Plant was a P3 arrangement: where they designed and built it, and then they operated it for twenty years, to 2020. Then the city put out a request for qualification followed by a request for proposal and the (blue-green) algae issue came up. We went a slightly different route after that. We essentially negotiated a five-year extension with Veolia to allow for the upgrades to deal with the blue-green algae mitigation.

WT: One of the reasons we do the City Water series is because we are trying to get across, most Canadians realize that bottled water is harmful to the environment, yet Canadians still buy bottled water by the millions, can you speak to that? If people are buying bottled water, does that drive your cost up? Can you give me an idea the cost of your water and why people should be drinking your water instead of buying bottled?

Taylor: There are two aspects to that. One aspect is, in the area here, one litre of bottled water costs $2. For that same $2 of city water, you will get 1000 litres. That’s a cost difference.

There are all different kinds of bottled water; some of it comes from fully treated water treatment plants, which the bottling companies bottle themselves, but it is essentially city-treated water.

There are companies that do that, there are companies that sell distilled water, or spring water, or artesian well water, melted iceberg water (laughs), all different ranges. A lot of people don’t realize that a lot of the time when they are buying bottled water, it's from a water treatment plant that a large bottling company has taken and bottled.

WT: I have noticed in some cities, they seem to have an active advertising campaign to convince people to go with tap water instead of buying bottled, do you have such a thing in Moncton?

Taylor: No. We don’t encourage drinking bottled water, but we don’t have an active campaign.

WT: Last question, now that BC has so many issues, have you addressed how climate change will affect your water plant. What steps are you taking around that?

Taylor: Our water treatment plant itself would not be subject to flooding, it sits on very high ground, we pump water from our reservoir up to our treatment plant. So, there is no risk of flooding from climate change, but there could be other impacts and changes to the raw water, which our water treatment plant would then have to adapt to. For example, forest fires can change raw water quality in a reservoir if you’ve got a forest fire near your reservoir. Ash and runoff can certainly change raw water parameters that impact treatment. We do have a fairly robust treatment facility, so we have some processes in place to help that. Our new clarifier process will also help with turbidity, which is essentially particulate matter in the water. We will better be able to deal with climate change-related issues now than with our previous system, better able to deal with turbidity coming in the raw water.

WT: What is the state of your city infrastructure? Some cities have breaks, leaks, how is your infrastructure, your leak detection system?

Taylor: We used to have well over one hundred water main breaks per year. Then the City started investing heavily in replacing pipes, older pipes or those prone to breakage, over a 12-to-15-year period. There are many types of pipes in our distribution system, some are more prone to breakage than others. When the replacements were done, on some streets, the water, sewer, and storm pipes were replaced.

New asphalt, curb and sidewalk were also installed. There are other streets where only the water pipe was replaced, so rit was a heavy investment. Now we get 30 to 50 water main breaks per year.

WT: That’s a huge improvement, that’s amazing. Thanks for doing this, Nicole, I will wrap it up there, have a good day.

Correction: The Moncton Overview was amended to include information on Lead Pipe Connections which was provided by the City.

|